The below post may contain affiliate links. This means we will receive a commission if you purchase through our link, with no extra cost to you. As an Amazon Associate we earn from qualifying purchases. Read our full disclaimer.

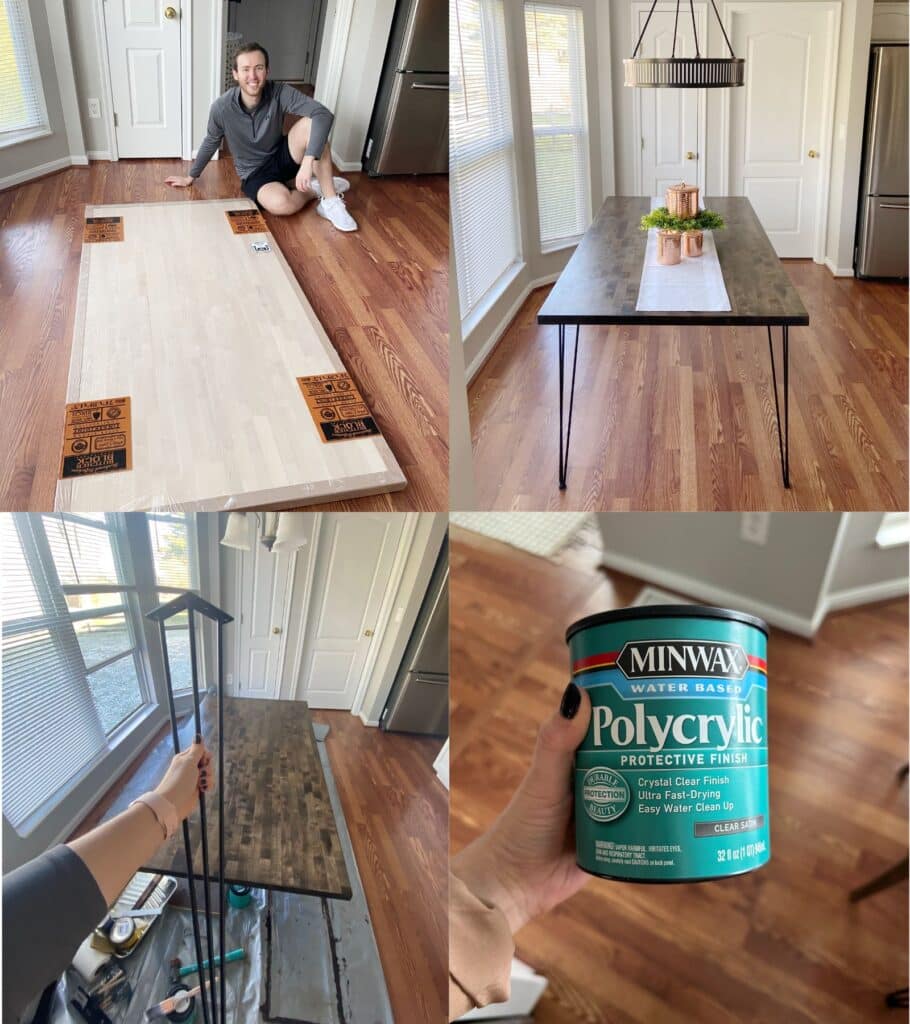

In this post, I’ll be showing you how to seal butcher block with Polycrylic! I’ll also explain why it’s the BEST, and only sealer I use for butcher block.

Alright, so you’ve just completed a DIY butcher block desk, or installed butcher block countertops.

Great choice! Butcher block is absolutely gorgeous and is an instant upgrade to any space. It’s strong and durable, but we want it to last as long as we possibly can.

That’s exactly why we seal butcher block!

How to seal butcher block with Polycrylic (step-by-step guide)

It’s extremely easy – you can feel confident going into this project! 😊

The best part is it’ll only take you about 10-15 minutes to actually do the work, between putting the Polycrylic on and sanding it once it’s dried. The majority of the time is just waiting for the thing to dry!

First and foremost, don’t shake Polycrylic, or polyurethane in general! Mix it with a stirring stick.

You MUST stain butcher block before sealing (if you are choosing to stain your butcher block). So if you haven’t done that yet, I’ll be here waiting. 🙂 Essentially, once the Polycrylic is on, staining cannot happen.

And here’s an extremely important fact about those rags you used for staining. You MUST safely dispose of staining rags as they are highly flammable.

Read this article, How to Safely Dispose of Staining/Rags Materials by Handmade Home Co.

Materials Needed

- Minwax Polycrylic Water-Based Sealer (Clear Satin)

- Sponge Brush

- 220-Grit Sandpaper

- Microfiber Cloth or Paper Towels

- N95 Particle Masks (it’s about to get stinky!)

To get started, we will need 3 coats. Oh, and now might be a good time to open those windows for the smell!

1. The First Coat of Polycrylic

Using a new sponge brush, begin to brush on the Polycrylic. Be sure to go with the grain of the wood so that it blends nicely with the butcher block.

Just get a thin layer on there, no need to go crazy with it! Enough to cover the surface.

With Minwax Polycrylic, it is a fast-drying top coat so you should be good to sand after 2 hours.

If you’re making a DIY butcher block desk or DIY butcher block kitchen table like I have, you’ll want to ensure that you flip the piece over and do the other side once dry. But for countertops, lucky for you, you’ll only have to do the top and sides of the butcher block.

2. LIGHTLY Sand!

Once your first coat is dry, take your 220-grit sandpaper and LIGHTLY sand going with the grain of the wood. I repeat, LIGHTLY start sanding the entire surface of your butcher block. You should just barely be applying pressure with the sandpaper.

The main goal of why we are sanding is so we can get the first coat to a point where it’s rid of all small bumps and any other imperfections. Do this over the entire surface not just the visible imperfections, so it evens out the entire piece.

Take a damp microfiber towel, and wipe down the entire surface to get rid of particles before the second coat of Polycrylic. The dampness will make it easier for particles to stick to your cloth so you can completely remove them from the surface.

3. Additional Coats of Polycrylic

Each coat of Polycrylic will be the same exact thing as the first coat. Apply Polycrylic, let it dry, sand it, and wipe it. I recommend at least 2-3 coats of Polycrylic to ensure your piece is nice and protected.

When you get to the last coat of Polycrylic, you will NOT be sanding once dried.

With this being said, for your last coat, be sure to brush on the Polycrylic with nice even strokes since what you see is what you’ll get!

Again, just enough Polycrylic to cover the surface of your butcher block, and be sure to go with the grain of the wood. Don’t cake it on there. 😜

4. Hello Sealed Butcher Block!

And just like that, you have a beautifully protected butcher block surface. Continue reading to hear everything you’re wondering about sealing butcher block!

Butcher Block Polycrylic or Oil

A quick Google search on sealing butcher block may make things more confusing than simple.

Polycrylic? Polyurethane? Tung oil? Mineral oil? There are plenty of options, but what’s the best way to seal butcher block? The answer is: it’s really up to personal preference. BUT I do highly recommend one over the others.

Why I recommend Polycrylic

Minwax Polycrylic Water-Based Sealer (Clear Satin)

Once you’ve stained that beautiful piece of wood your desired color, Polycrylic will make sure it stays as beautiful as day 1!

Polycrylic creates a water-resistant barrier around your butcher block. There’s no risk of staining with spills or anything else. There is no penetrating this stuff, so there’s zero worry in that department.

You also only need to seal once (2-3 coats) with Polycrylic. After that? You’re done. For a very long time before ever thinking about having to retouch!

Need a butcher block to seal?

I’ve used the Hardwood Reflections butcher block from Home Depot for both my DIY kitchen table and DIY home office desk. Let me just say the results are incredible. Like sometimes I just sit and stare at them lol. They’re that pretty!

It comes in different sizes for all of your project needs, as well as different types of wood. Birch is what I’ve used and will continue to use for my future projects.

It comes pre-sanded which is easier for staining (if you choose to stain your butcher block), and it’s just so simple to work with. 10 out of 10, highly recommend!

Is Polycrylic actually polyurethane?

The short answer: No!

There’s a big debate about whether or not Polycrylic is the same as polyurethane. So I reached out to the source themselves to settle it: Minwax!

Minwax plainly stated that Polycrylic is not considered a polyurethane. So there you have it!

Polycrylic is in a league of its own. It’s a water-based protective top coat that contains urethane (yes the other half of poly-urethane). But it’s acrylic based – hence Poly-crylic. So it has similar protective qualities as polyurethane.

I call it the DIYers polyurethane, although it’s not a polyurethane. Just because it essentially does the same thing and it’s seriously SO easy to work with.

So is Polycrylic the same as polyurethane? It has been officially stated that it’s not.

While there are similarities between Polycrylic and polyurethane, it’s important for the DIYer to know the difference, and where to use each product.

Polycrylic

- Polycrylic is the name of a water-based top coat product created by Minwax.

- Best when used to seal indoor projects or low-traffic areas to protect surfaces against damage. Indoor use only.

- Eco-friendly, has lower VOCs (so less toxic vapors), and for the DIYer, it dries very quickly.

- Provides you with a crystal clear protective finish. If you want your wood, stained or not, to retain as much of its natural color as possible, use Polycrylic!

- While it’s durable, it’s not as durable as oil-based polyurethane. Polycrylic and water-based polyurethane are both prone to scratching because they’re both water-based. But oil-based polyurethane will be ever-so-stronger.

- According to Minwax, Polycrylic is non-flammable.

Polyurethane

- Polyurethane can come in oil-based or water-based finishes.

- Best used for sealing outdoor surfaces that are exposed to the elements or high-traffic areas. It’s also very common to finish real hardwood floors with oil-based polyurethane because of its durability.

- Higher VOCs when compared to Polycrylic and takes longer to dry.

- Water-based polyurethane is more prone to scratching, similar to Polycrylic, because of its hard clear coat.

- Oil-based polyurethane is more prone to denting because the final result is a tad softer than water-based – but it’s better against scratches, moisture, and heat.

- Oil-based polyurethane gives wood a slight amber-ish, yellow-ish hue.

- Oil-based polyurethane is also flammable, while water-based is not. This mostly applies to the wet product and fumes, but I would still exercise caution in both wet and dried states for both types of polyurethane.

Can you seal butcher block with polyurethane? Absolutely! You’ll have to weigh the advantages and disadvantages of polyurethane and Polycrylic.

But this post is all about how to seal butcher block with Polycrylic. 🙂

My personal thoughts on it: I will still pick Polycrylic over water-based or oil-based polyurethane for sealing butcher block, or any other project. Why? Because it’s a lot easier to work with, it’s less harmful for you, and while it’s not as durable as polyurethane, it’s pretty dang durable!

Is Polycrylic food safe for butcher block?

The short answer: Yes – if you don’t chop directly onto it!

You’ve probably seen some buzz when searching around whether Polycrylic and polyurethane, are food-grade and safe in your kitchen.

Yes, Polycrylic is essentially a thin coat of plastic between your wood butcher block surface and you. But here’s the comforting bit.

The FDA approves polyurethane (which would include Polycrylic in this instance) in its cured state as safe for contact with food. The key word here is contact. Just remember, cured does not mean dry. Once dry, it’s still going through a chemical process for up to 30 days to become cured.

At the end of this curing process, Polycrylic and polyurethane are considered non-toxic and safe to come in contact with food. So there’s really no specific “food grade polyurethane for butcher block”. Cured Polycrylic and polyurethane are safe for contact with food!

With that being said, I would NOT, and I repeat AVOID, chopping food with a knife directly on a surface that has been sealed with Polycrylic or polyurethane.

Why? Because while food touching cured Polycrylic and polyurethane is safe, if you’re chopping directly on top of the butcher block then of course you’re risking getting particles in your food.

Now I don’t know many people who chop food directly on their countertops, but the SUPER simple fix for this is, you guessed it, use a cutting board!

But that goes with anything. I mean think about chopping on really any surface, you’re going to deal with the same thing, it’s not just sealed butcher block.

So while you may see plenty online about Polycrylic and polyurethane being toxic or not food-safe when coming in contact with food, it’s simply not true.

As long as you allow Polycrylic to cure for 30 days after applying, and you’re not chopping directly on it, you shouldn’t have any worries.

I did the research for you!

For further reassurance, I use Polycrylic to seal all of my DIY projects involving stain and wood. I’ve had plenty of experience with sealing, and I truly care about ensuring what I’m doing is safe for my family and me.

I wouldn’t do it if I didn’t fully trust the safety of the product and I’ve done LOTS of research on the subject.

In fact, I sealed my own DIY butcher block kitchen table several years ago with Polycrylic and I’m so happy that I did.

Whether it’s butcher block countertops, a butcher block desk, or a butcher block table, I HIGHLY recommend using Polycrylic to seal butcher block.

Drying time vs. Curing time: when can I use my newly sealed butcher block?

When using Minwax Polycrylic, you’re ready to use your sealed butcher block after 24 hours of applying your last coat…with caution! What do I mean by “…with caution”? Don’t let that freak you out! Let me explain to alleviate any anxiety.

After 24 hours, your top coat will be completely dry to the touch. However, it still needs to go through the curing process, which takes 30 days.

What does curing mean? Curing is the molecular process that Polycrylic and polyurethane undergo when exposed to oxygen, which allows it to bind and be as strong as it will ever be. As I just mentioned, this process does take 30 days. Bet you didn’t think you’d have a little science lesson today haha.

That doesn’t mean you can’t use your butcher block for 30 days, that just means you have to be a little more gentle than you typically would when using a countertop. During this period of time, while all of the fun science is happening in the background, your sealed surface is a little more prone to scratching before it’s completely cured.

Essentially, just be attentive to how you are using your sealed butcher block.

Place down, pick up, no scooting – those are your instructions for the next 30 days. 😉

For kitchen countertops, maybe opt for a silicone heat-resistant mat. This might be a nice-to-have long-term since Polycrylic is not heat-resistant like some stone countertops. For desks, you could use a desk mat.

After 30 days, you’re in the clear to drop the “caution” and use your butcher block how you typically would use any other surface.

How do you permanently seal a butcher block?

You may also be asking yourself, how often do you have to seal butcher block?

Well, I’m here to tell you that’s another advantage of Polycrylic – it permanently seals! And better yet, you only have to seal it one time (2-3 coats) and it’s good for a very long time. Of course, the caveat there is if you ever get any scratches, you may want to touch up your surface.

If you use tung oil or mineral oil to seal your butcher block, it’s a different story.

Tung oil will need at least 6-7 coats, if not more over time for touch-ups. This type of sealer requires a lot of patience as it penetrates very slowly, taking at least a couple of days with each coat to completely dry. It’s also pretty expensive considering you will need a good amount of it, and likely won’t be a one-time buy.

Mineral oil needs to be applied almost once a month, or in other words, a lot more than the other types of sealers! That means removing the items from your countertop, table, or desk month after month just to seal. I don’t know about you, but I don’t have time for that!

To help explain the difference even further, the oil sealers soak into the wood for protection, whereas the Polycrylic adds an extremely thin layer of protection on top of the surface.

Polycrylic Advantages and Disadvantages

Let’s take a look at the advantages and disadvantages of using Polycrylic as a sealer for your butcher block.

There truly aren’t that many disadvantages, unless you’re completely set on using your butcher block countertop as one large chopping block.

Polycrylic Advantages

- Fast drying (2 hours)

- Food safe once cured (30 days after applying)

- Semi-permanent – just one time (2-3 coats) and you’re good! Semi-permanent, because you can always sand it down.

- Creates a water-resistant seal around your stained butcher block – making it spill-proof. While it will protect your wood from water damage, Minwax still does not consider the product waterproof. But when they say it’s not waterproof, they’re talking about outdoor application exposed to rainy days kind of waterproof.

- Less time-consuming process

- Easy to apply

- According to Minwax, non-flammable

Polycrylic Disadvantages

- Cannot use your countertop for chopping

- Polyurethanes can yellow over time depending on the product, but that’s more just a general statement for polyurethane – Polycrylic doesn’t really have this issue as it’s a water-based clear coat

- Some say Polycrylic can have a slightly unnatural sheen, but I’ll let you decide!

Tung Oil Advantages and Disadvantages

Now that we’ve covered the good and the bad of Polycrylic, let’s take a look at the advantages and disadvantages of using tung oil!

Tung Oil Advantages

- Completely non-toxic options for directly chopping on a countertop – not all tung oils are food grade, so be sure to do your research!

- Provides a natural shine – lets the stain do the talking

- No yellowing over time

- Easy to apply

Tung Oil Disadvantages

- Multiple coats (6-7) with additional for upkeep over time

- Slow penetration – up to 5 days to completely dry with each coat

- Susceptible to damage from water

Something Polycrylic and tung oil also both have in common is that they do NOT smell good. So crack those windows open, get that mask on, and get the fans going!

How to clean a surface sealed with Polycrylic?

Whether it’s a butcher block kitchen table, or butcher block countertops, you’re going to need to clean your sealed surfaces after use.

The good news is that you can use a simple all-purpose cleaner spray to clean a surface sealed with Polycrylic.

My go-to that I’ve been using on my butcher block kitchen table for years is the Method All-Purpose cleaner. I especially love the Pink Grapefruit scent!

What is the best product for sealing butcher block?

Minwax Polycrylic Water-Based sealer is hands down the best way to seal butcher block! Get it in Clear Satin.

I know a lot of people ask “Can I use Minwax Polycrylic on butcher block?” And the answer is, that’s the ONLY thing I recommend.

As I said, I have used Polycrylic to seal all of my staining and wood projects, and I have never used anything different.

Remember how I said there’s a product that won’t yellow over time? Well, this is it! Minwax Polycrylic is one of the best, if not THE best, top coats you can use for non-yellowing because it is water-based and it dries as a crystal clear coat. Only oil-based polyurethanes will yellow.

For even more reassurance, I have a piece in my home that I sealed with Minwax Polycrylic water-based sealer 10 years ago, and guess what? No yellowing!

Polycrylic is available in the following sheens: Clear Satin, Clear Semi-Gloss, and Clear Gloss. But like I mentioned earlier, the glossier the finish, the more apparent any future scratches might be.

I find that Clear Satin is pretty close to a matte finish, but you will catch the slightest shine depending on the lighting and angle (as seen in the pics). This is perfect for my liking, but everyone has their own taste! 😊

Other Posts You Might Like:

Hi there I am planning to do butcher block counter tops and I’m curious about the countertop around the sink and above the dishwasher. Do I need to seal it differently around those areas and would you put something underneath the counter top in those areas?

From the comments I’ve read, I take it that it is ok to stain the top before sealing it with Polycrylic?

Hi Larry! Yes, that is correct! You will want to stain your wood with 1-2 coats of stain, let it dry, and then apply the Polycrylic. Feel free to return to this post if you have any questions throughout the process. I hope your project turns out amazing! – Alley

Can polycrylic still be used on a butcher block table after you’ve applied a food safe oil if you’ve changed your mind on a sealer??

Hi Alley!! We just had a butcher block countertop that has been sealed with polyurethane installed in our bar area. We are still in the 30 day curing phase so just wiping dust off with a microfiber cloth. What do you suggest cleaning with?

Hi Deanna! I bet your bar area looks beautiful! 🙂 I think that the microfiber cloth should be just fine for the time being while your polyurethane cures. Once it’s fully cured, you can simply use a mixture of dish soap and water with a microfiber towel or hand towel to clean off your surface! -Alley

Our butcher block countertops were protected with beeswax before we bought our house, so we have been using the same method. We have discovered that the wax needs to be re-applied every 2-3 months (kind of a hassle) and we are constantly (and quickly!) wiping up anything that could potentially stain the wood such as berry juice or splashes from a yellow curry sauce, etc. Is it possible to remove the beeswax and replace it with Minwax Polycrylic? Thanks for any tips you can provide.

Hi there! Excellent question and a place others might find themselves in when taking over the maintenance from previous homeowners. I believe it’s definitely possible to remove and have heard of other people completely removing beeswax (mineral oils, tung oils, etc.) from their butcher block. I haven’t personally had experience with this myself, but with a little TLC, you can get your countertops back to it’s raw form and be able to use Minwax Polycrylic as laid out in this post. My advice is searching on YouTube – my absolute best friend that has saved me so much time with projects 🙂 Although it might be a process, I’m sure not having to go through the hassle of having to reapply beeswax every couple of months will be worth it in the end! Wishing you the best! -Alley

can you use the butcher block while it is during? 30 days. that’s a long time to be without a counter

This is a really great question! Minwax Polycrylic takes 24 hours to dry to be ready for everyday use with a touch of caution. The 30 days is the time that polyurethane takes to cure which allows for the process of the molecules in the polyurethane to fully bind and be as strong as they can possibly be. So during those first 30 days, just be extra careful not to scoot dishes, cutting boards, etc. around on the countertop as this could lead to scratches in your top coat! You can still work on your countertop during this time as the polyurethane will be completely dry, just be a little more gentle than you typically would. At the end of the 30 days of the curing process, you’re in the clear to drop the caution! 🙂 -Alley

Thanks for all the pointers and tips! I’m feeling confident enough to finally tackle this project on my own 😊

Do you recommend sanding the butcher block before applying the first coat of polyurethane? My goal is the keep my butcher block as natural looking as possibly without doing any stain, so just curious if additional sanding is necessary.

I’m so happy this was helpful and I’m so excited for your project! I love the idea of keeping the butcher block looking natural – they’re so pretty to begin with. Depending on where the butcher block came from, it actually might already be pre-sanded! For instance, my butcher blocks are the Hardwood Reflections brand and I know those come pre-sanded.

However, since you aren’t doing stain, I would just do a quick “feel” test. Run your hand across the surface and see how smooth it is. If it’s feeling really smooth and I were in your shoes, I would just start applying the first coat of polyurethane without sanding! The main reason for sanding prior to staining is to get those tiny little wood fibers standing up so that the stain can soak into the wood better – but without stain, I don’t see sanding as a necessary step! 🙂 This will definitely save you some time! -Alley

Beautiful job! I’m about to finish my countertops and had planned to use gloss Polycrylic. What are your thoughts on using gloss vs satin?

Thank you so much! I have personally used satin Polycrylic for sealing all of my projects involving wood – and there are several reasons I personally go the satin route.

-If you’re applying in a high-traffic area such as a kitchen, gloss tends to shine (no pun intended) a little more light on any small scratches that may appear over time. So if you think about a scratch on a shiny surface, gloss will call more attention to it.

-Gloss is also a little more tricky to touch up if you need to retouch any areas over time that may have gotten a nick or scratch. This is because it can cause your touch-up area to appear more glossy than the rest of the piece.

-I had my reservations about satin when I started working with it years ago, but I found that it actually does have more shine than I’d thought – enough to make me happy! 🙂

If you want to see a more real-life example of satin in action, I recommend checking out this link: https://homebyalley.com/diy-butcher-block-desk/. In the post, I walk through creating a butcher block desk, but I’m pointing you here because there are better pictures of a finished product using satin Polycrylic on butcher block. You’ll see it does actually have some shine! You can’t really go wrong with either, but just wanted to share my thoughts around why I love satin! I hope this helps, and I’d love to know what you end up going with! -Alley

Hello, I used to satin like you did and looked at your link, but mine is not that shiny, did I did something wrong?

Hi Hailee! I hope you enjoyed using Polycrylic for sealing your butcher block! To answer your question, I don’t think that you did anything wrong! It may be that the picture we provided didn’t fully capture what the product is like in real life. The “Clear Satin” finish does have a slight shine to it when the light hits it just right. I specifically took the pictures like this so you could see the slight shine. However, I wouldn’t necessarily describe “Clear Satin” as shiny in an everyday scenario.

With that being said, you can still get the shininess you are craving with Polycrylic. And, there are a couple different options to get you there.

1. It may be that you just need an additional coat of the “Clear Satin” Polycrylic. You can always try applying an additional coat but put it on a little thicker this time around. I am not sure if this is the best option for you just because I can’t see your piece.

2. If you are looking for a little bit more shine than the “Clear Satin” finish, you could always try the Polycrylic “Semi-Gloss” finish. This is one step up on the shininess scale! The good news is that the steps are the same and you can apply it over the last coat of “Clear Satin”. First, lightly sand the entire surface with 220-grit sandpaper (going with the grain). Second, wipe down the surface with a microfiber cloth to remove any sanding dust. And third, apply the new coat of “Semi-Gloss” over the entire piece. I am hopeful that this will give you the shine you are looking for!

Before you commit to any new finish, I always recommend looking up videos on YouTube/TikTok so you can see the different sheens in action. It’s always a little hard to tell from pictures! I would also recommend doing a little test spot on your piece either under the butcher block or on a inconspicuous place to see if you really like the sheen.

Sometimes it may take a little bit to really find the finish or sheen you love, and that’s okay! Keep me updated on what you end up doing! 😊 -Alley

I have a new butcher block table top and I have sealed with mineral oil can o still use polyurethane for a finish thanks

Good question! Unfortunately, mineral oil is a non-drying oil and therefore polyurethane will not be able to adhere properly to it. This goes for any top coat you’d try applying over mineral oil since non-drying oil essentially never hardens and remains liquid. All hope is not lost! I’ve heard of people switching from mineral oil to polyurethane but it requires a little bit of extra effort. If this is something you’re interested in doing, below are the steps for removing mineral oil from butcher block:

1. Sand the oiled surface with 120-grit sandpaper.

2. Use a microfiber cloth to wipe away the sanding dust.

3. Apply a good amount of mineral spirits to a new microfiber cloth and rub it around the surface of your piece.

4. Allow the mineral spirits to sit on the surface for several minutes (based on the product instructions).

5. Repeat until all mineral oil is gone.

6. Follow the steps in this post to apply polyurethane!

I am wondering what is the best stain to use if you want the butcher block to keep the light coloring it came with?

Hi Audra! This is a great question! This isn’t something I’ve ever done before but I’m also curious about it. However, Pickled Oak by Minwax may be a stain you want to look into – it looks like it might keep the original color you love. My go-to when trying to figure out stain colors is to search what the stain color would look like on the specific type of wood I am using for my project. This will help you get the best visual of what it would look like for yours!

You could also just use polyurethane without staining. However, something to keep in mind when using polyurethane is that it’s always going to slightly darken the original wood color.

One last tip: test out whatever stain color you end up choosing on the bottom of your board to make sure you absolutely love it before committing! I wish I had more of a direct answer for you but I hope this was helpful! I would love to hear how your project ends up and which stain color you ultimately choose! – Alley